Deformity Life Cycle, otherwise called Bug Life Cycle, is the excursion of an imperfection, the cycle which a deformity experiences during its lifetime. It shifts from association to association and furthermore from task to extend, as it is represented by the product testing process and furthermore relies on the apparatuses utilized.

Defect Life Cycle – Workflow

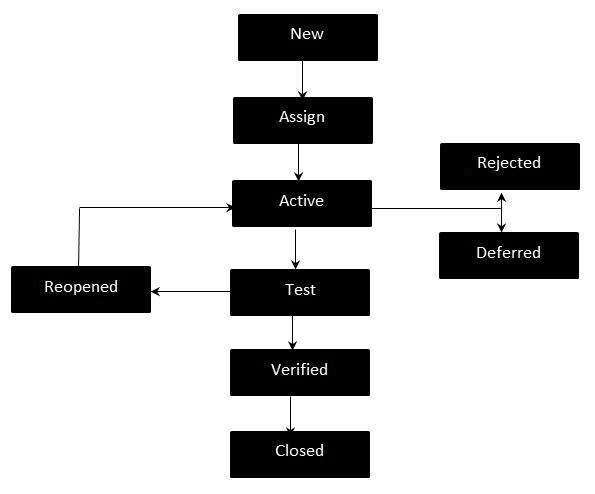

The accompanying chart shows the work process of a Defect Life Cycle.

States of a Defect Life Cycle

Following are the various conditions of a Defect Life Cycle.

- New − Potential imperfection that is raised but to be approved.

- Doled out − Assigned against an improvement group to be tended to.

- Dynamic − The Defect is being tended to by the designer and examination is under advancement. At this stage, there are two potential results – Deferred or Rejected.

- Test/Fixed/Ready for Retest − The Defect is fixed and prepared for testing.

- Confirmed − The Defect that is retested and the test has been checked by QA.

- Shut − The last condition of the imperfection that can be shut after the QA retesting or can be shut if the deformity is copy or considered as NOT an imperfection.

- Revived − When the imperfection isn't fixed, QA revives/reactivates the deformity.

- Conceded − When an imperfection can't be tended to in that specific cycle it is conceded to future discharge.

- Dismissed − An imperfection can be dismissed for any of the three reasons – copy deformity, NOT a Defect, Non Reproducible.